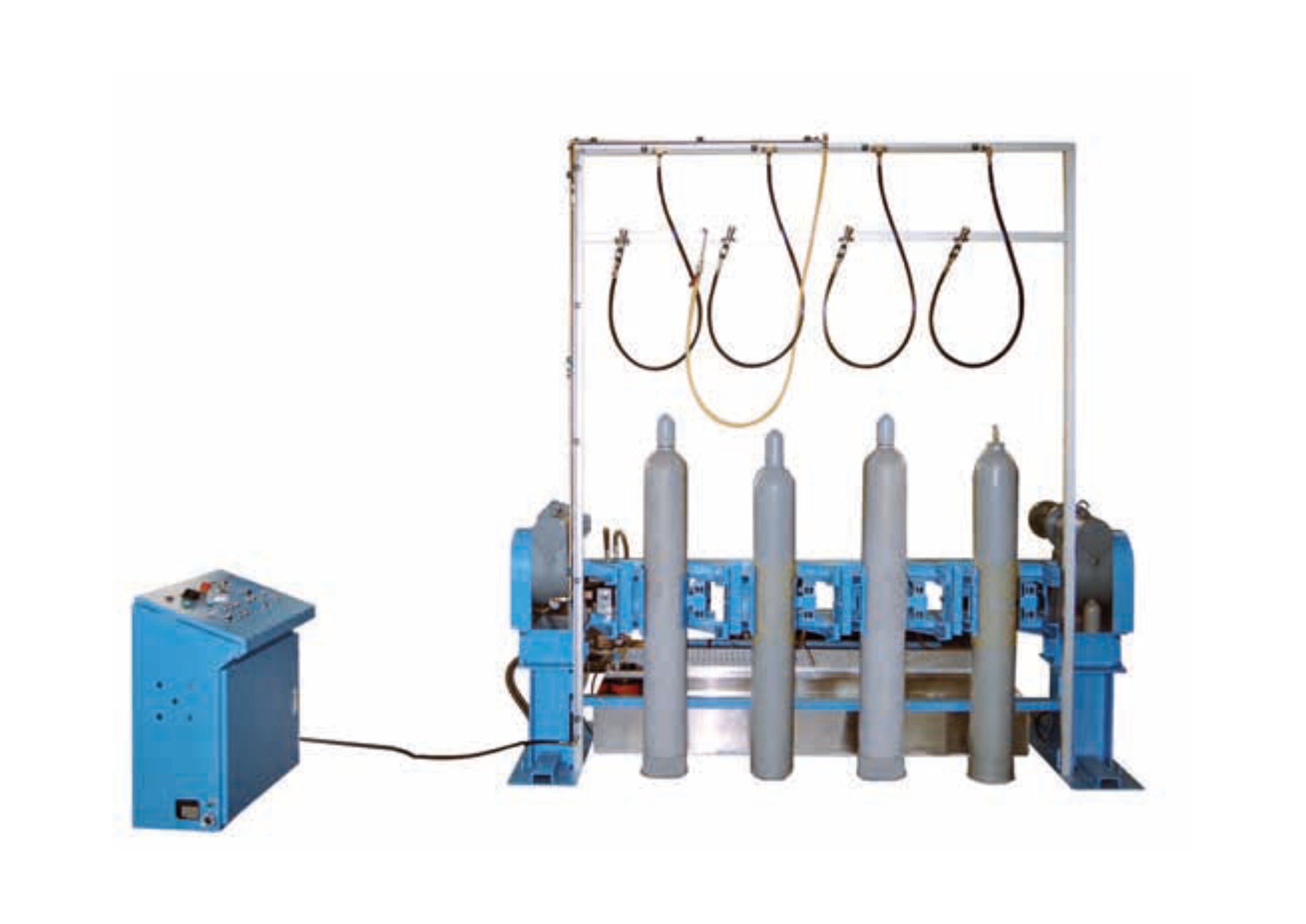

TIPPING DEVICE MODEL IV

The Model IV tipping device is used in conjunction with a high pressure test rig. It is used for clamping and tipping steel cylinders to be emptied after the pressure water test.

A maximum of 4 steel cylinders can be clamped and tipped at the same time. Each steel cylinder is clamped separately by means of a hydraulic cylinder. The equipment is operated from the operator's position. The steel bottle can be rotated up to a maximum of 170°.

The steel bottles are emptied in the tipped state into a water collection tank located behind the tipping device.

Within this tipping range, the bottle can be stopped in any arbitrary position.

Quick-load adapter for tipping device, model EM:

Screw-on adapter with quick-release lever for water pressure testing of CO2 bottles with connection thread (W 28.8 x 1/1/4")

The screw adapter is equipped with a quick coupling, which allows quick adjustment to the pressure test hose

OPTIONAL ACCESSORIES:

Water filling unit

Unit for high pressure testing up to 450 bar

Unit for bottle drying with drying probes

Tank with heater (500 l capacity)

Splash protection device

The equipment is equipped with more or less control points

TECHNICAL DATA

Dimensions (l x w x h): tipping device: approx. 2750 x 1800 x 3000 mm

Operating position: approx. 800 x 600 x 1000 mm

Steel cylinder dimension: (Ø) approx. 205 to 270 mm

Steel bottle height: approx. 1200 to 1800 mm

Drive: Hydraulic power unit: 3 kW, 3 phases 230/400 V, 50 Hz

Hydraulic pressure: max. 160 bar

Drive for tipping device: 3 phases 230/400 V, 50 Hz, 2 x 3 kW

Settings

Settings